Technical Data

HPL

This section of the HPL Package contains crucial technical data, useful for everyday application of HPL SWISS KRONO. A summary of information for everyday use, such as: product parameters, storage conditions, or cleaning and maintenance methods.

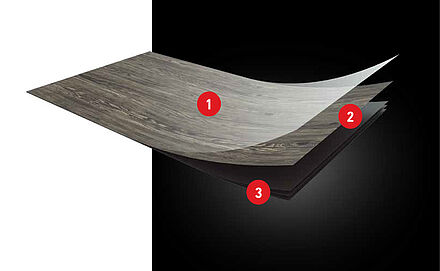

Structure

HPL laminates are produced in sheets or rolls. The upside of each sheet has a decorative layer – unicolour, imitating wood or stone, or a whimsical pattern.

The underneath is pre-polished and prepared for gluing or joining with a carrier board.

HPL contains several layers: Each layer is made of a different kind of paper, prepared and produced in a different way.

1. Overlay protective layer - top invisible layer is special paper impregnated with melamine resin which makes the HPL highly resistant to abrasion and scratching.

2. Decorative layer – printed paper impregnated with melamine resin with various patterns: wood-like, stone, fancy or in monochromatic colours.

3. Core – impregnated paper with phenol resin.

Room conditions during HPL laminates processing

Room humidity and temperature have a crucial influence on HPL laminate linear dimension changes.

Optimum conditions:

Temperature: 18-22°C

Air humidity: 50-60 %.

Note: Storage and room conditions during processing have a direct influence on HPL SWISS KRONO laminates gluing and processing results.

Processing

HPL SWISS KRONO processing should be performed on a stable, flat and even surface. The laminate should be placed with the decorative side up. Do not let the laminate vibrate or tremble. Sharpness and proper movement of tools are crucial. Decorative side cracks, breaks or bumps result from inappropriate processing or wrong tool. Use standard carpenter’s tools, such as circular bench saws, hand-held circular saws and jigsaws, for cutting.

Saw manufacturer’s recommendations should be observed.

Good quality of the processed edge depends on:

- teeth shape

- teeth number

- cutting speed

- feed speed

HPL Swiss Krono laminate cutting

Packaging

HPL format available in stock (standard):

HPL in sheets:

• 4100x1320x0.5 mm

HPL formats available on request

HPL in sheets:

• widths: 630 - 1320 mm and 2080 mm

• lengths: 500 – 5600 mm

• thickness: 0.15 – 1.2 mm

HPL in rolls:

• Thickness range: 0.20 to 0.60 mm

• Maximum roll diameter: 400 mm

• Core diameter: 150 mm

Gluing HPL SWISS KRONO

Decorative HPL SWISS KRONO laminates may be used in a variety of ways by gluing them to carrier wood-derived materials..

When making combined elements out of HPL SWISS KRONO and carrier materials, it is crucial to use proper gluing systems matched to the place of use of the finished product.

Before gluing, clean both sides of the laminate and the carrier material thoroughly. All, even the smallest smudges and stains must be removed.

During gluing, follow all adhesive manufacturer recommendations on both adhesive layer application and proper stress.

The following kinds of adhesives are appropriate for wood-derived materials:

Dispersive adhesive

e.g. PVAC = white glue

Condensing adhesive

e.g. urea-formaldehyde/melamine, resorcinol, phenol resins

Contact adhesives

e.g. neoprene adhesives

Reactive adhesives

e.g. epoxy, unsaturated polyesters, polyurethane adhesives

Hot-melt adhesives

e.g. polyurethane hot-melt adhesives

| Adhesives | Temperature resistance | Gluing method | Warning |

|---|---|---|---|

| Dispersive adhesive | |||

| PVAC | from -20 to 100 °C | manual, with hand roller/spatula or machine, with roller, hot or cold forging |

screw clamp or stationary press |

| Two-ingredient PVAC | |||

| Condensing resin | |||

| Urea-formaldehyde resin | from -20 to 150 °C | manual, with hand roller/spatula or machine, with roller, hot forging |

stationary press with heat source |

| Urea-melamine resin | |||

| Phenol, resorcinol resin | |||

| Contact adhesives | |||

| without hardeners | from -20 to 70 °C | manual, with hand roller/brush, adhesive application on both sides, short strong press |

short strong press with roller |

| with hardeners | |||

| Reactive adhesives | |||

| Epoxy/polyurethane | from -20 to 100 °C | manual, with hand roller/spatula or machine, with special roller |

with roller and providing heat |

| Hot-melt adhesives | |||

| EVA | from -20 to 90 °C | machine | usage in accommodation spaces |

| PA/PO | from -20 to 110 °C | ||

| PUR | from -30 to 140 °C | spaces of high humidity and thermal stress |

|

Carrier materials

To create the perfect surface, laminate HPL Swiss Krono should be used (glued) on both sides of the carrier material.

It is recommended to use laminates of the same parameters, particularly the same thickness, on both sides.

Remember to glue opposite laminate sheets to the carrier material in the same direction.

Failure to follow above recommendations may result in material deformation.

Carrier materials

- Particle boards

- MDF

- HDF

- OSB

- Plywood

- Wooden boards

Cleaning

SWISS KRONO HPL should be cleaned with a damp, soft cloth or sponge, with commercially available cleaning agents, such as a solution of dishwashing liquid. After washing with ordinary cleaning products, the laminate should be washed with clean water and wiped dry to obtain a smooth surface without streaks.

Before using any cleaner, read the attached description to make sure it is suitable for that type of surface. Do not use cleaners that contain aggressive or corrosive substances or agents that contain abrasive or glossy additives, as they may permanently damage the surface of the laminate. Larger dirt, such as from a marker, nicotine, nail polish or shoe polish, should be removed with spirit or an organic solvent (such as acetone), and then the laminate surface should be washed with clean water and wiped dry.

SWISS KRONO HPL is resistant to most substances that can cause stains, such as milk, tea, coffee, wine, syrups. Despite such high performance of HPL, it is recommended to remove residues of the mentioned products from the surface.

Special attention should be paid to such products as: blueberry juice, red beet juice or tomato paste.

EN 438-3 standard

HPL Swiss Krono laminates meet the requirements defined by the EN 438-3 standard.

EN 438-3 standard precisely defines the parametersand properties of all types of HPL laminates, including control procedures for unequivocal determining of declared material properties.

SWISS KRONO HPL is produced in accordance with the classification and typical use system contained in EN 438-3 standard, table 3:

- HGS - for horizontal applications, general purpose, standard use

- HGP - for horizontal applications, general purpose, postforming

- VGS - for vertical applications, general purpose, standard use

- VGP - for vertical applications, general purpose, postforming

The individual letters stand for:

- H - Horizontal use

- G - General purpose

- S - Standard

- P - Postforming

- V - Vertical use

Technical and performance properties of laminates in HGS and HGP types. General Requirements

| Property | Unit of measurement | Requirement | Test method |

|---|---|---|---|

| Thickness tolerance | mm | 0,5 - 1,2 mm ± 0,10 | EN 438-2.5 |

| Length tolerance | mm | +10 / -0 | EN 438-2.6 |

| Width tolerance | mm | +10 / -0 | EN 438-2.6 |

| Resistance to scratches | N | ≥ 3 | EN 438-2.25 |

| Abrasion resistance | turnover | IP ≥ 150, IP + FP/2 ≥ 350 | EN 438-2.10 |

| "Impact resistance (Small diameter ball)" |

N | ≥ 20 | EN 438-2.20 |

| Flatness tolerance | mm/m | ≤ 60 | EN 438-2.9 |

| Edge straightness tolerance | mm/m | ≤ 1,5 | EN 438-2.7 |

| Squareness tolerance | mm/m | ≤ 1,5 | EN 438-2.8 |

| Density | g/cm3 | ≥ 1,35 | EN 1183-1:2004 |

| Stain resistance | degree degree |

grupa 1 i 2 = 5 grupa 3 ≥ 4 |

EN 438-2.26 |

| Light resistance (xenon lamp) | Grayscale | ≥ 4 | EN 438-2.23 |

| Resistance to hot pot base (160°C) | degree | shiny surfaces ≥ 3 other surfaces ≥ 4 |

EN 438-2.16 |

| Steam resistance |

degree | shiny surfaces ≥ 3 other surfaces ≥ 4 |

EN 438-2.14 |

| Formaldehyde emissions | Class E1 | EN 717-1 |

Technical and performance properties of laminates in VGS and VGP types. General Requirements.

| Property | Unit of measurement | Requirement | Test method |

|---|---|---|---|

| Thickness tolerance | mm | 0,50 - 1,2 mm ± 0,10 | EN 438-2.5 |

| Length tolerance | mm | +10 / -0 | EN 438-2.6 |

| Width tolerance | mm | +10 / -0 | EN 438-2.6 |

| Resistance to scratches | N | ≥ 2 | EN 438-2.25 |

| Abrasion resistance | turnover | IP ≥ 50, IP + FP/2 ≥ 150 | EN 438-2.10 |

| "Impact resistance (Small diameter ball)" |

N | ≥ 15 | EN 438-2.20 |

| Flatness tolerance | mm/m | ≤ 60 | EN 438-2.9 |

| Edge straightness tolerance | mm/m | ≤ 1,5 | EN 438-2.7 |

| Squareness tolerance | mm/m | ≤ 1,5 | EN 438-2.8 |

| Density | g/cm3 | ≥ 1,35 | EN 1183-1:2004 |

| Stain resistance | degree degree |

grupa 1 i 2 = 5 grupa 3 ≥ 4 |

EN 438-2.26 |

| Light resistance (xenon lamp) | Grayscale | ≥ 4 | EN 438-2.23 |

| Steam resistance |

degree | shiny surfaces ≥ 3 other surfaces ≥ 4 |

EN 438-2.14 |

| Formaldehyde emissions | Class E1 | EN 717-1 |