SWISS KRONO creates a milestone for wood recycling in Poland

News | SWISS KRONO Poland

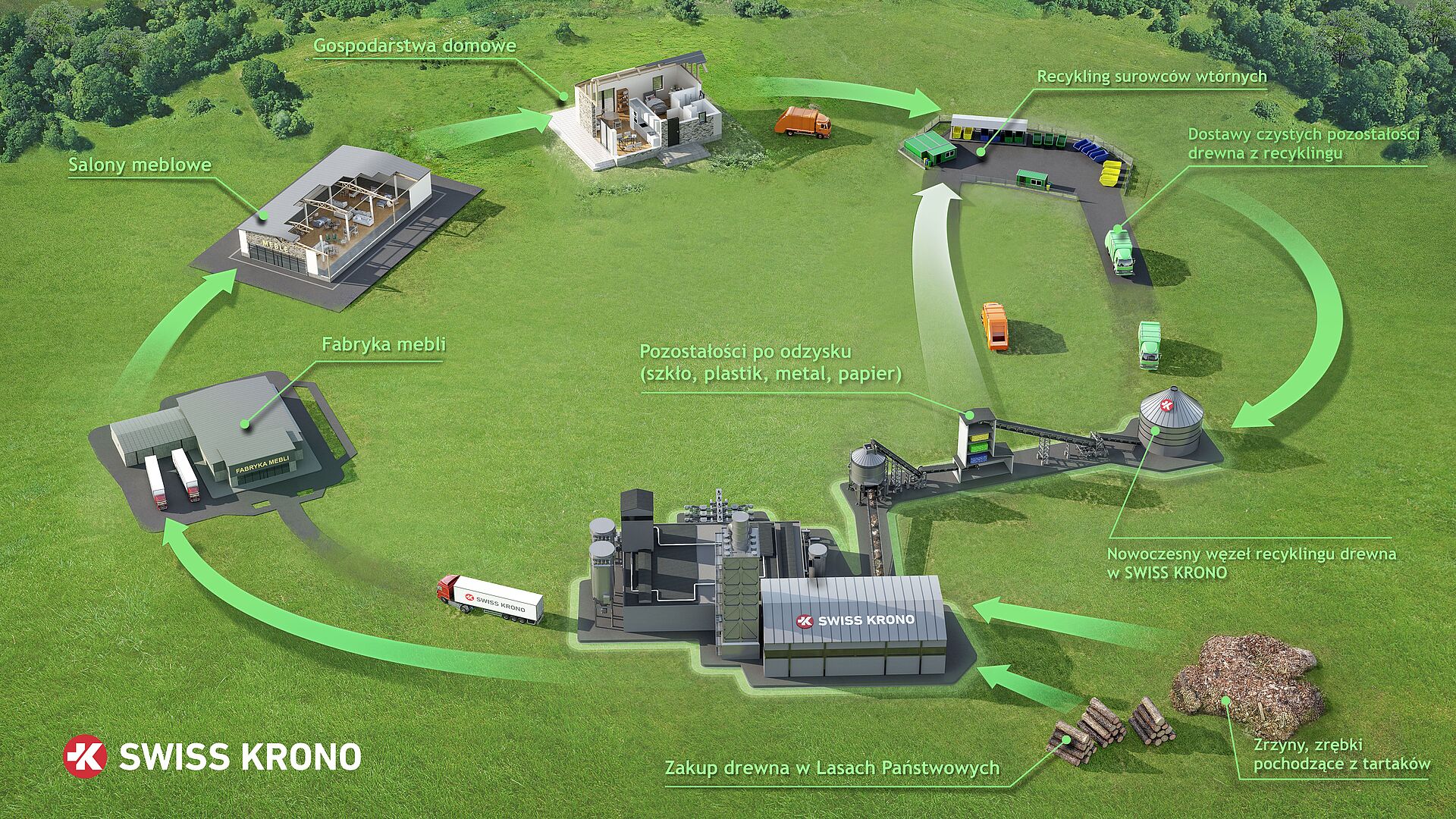

Up to 100,000 cubic metres of forest wood can be replaced by recycled raw material after the launch of a modern wood recycling centre at the SWISS KRONO plant in Żary. The plant will receive pre-cleaned raw material free of sand or nails, which will be used by one of the largest factories in Poland to manufacture new construction, furniture or floor panels.

In the second half of 2023, a wood recycling hub is planned to be commissioned at the SWISS KRONO plant in Żary.

- It's a milestone towards environmental protection and a circular economy – says Jędrzej Kasprzak, the commercial proxy of SWISS KRONO. - Ultimately, up to 50% of the raw material in the production of our building and furniture panels will come from recycled materials, as has been happening all over the world for several years now.

Recycled raw material of full value will come to Żary from specialised recycling companies (which sort out used furniture, floors, windows or demolition wood and pre-treat it to remove nails and sand). In the SWISS KRONO plant, it will be thoroughly cleaned on a new, automated line. All "foreign matter" such as metals, plastics and stones will be removed. The wood material will be then transformed into technological woodchips to be used in the production of panels, and the recovered raw material in the form of metals or plastics will be returned to the Selective Collection of Municipal Waste (PSZOK) for further processing and use.

- Thanks to this investment, we will create new jobs, help the environment and lower the cost of producing our panels. Moreover, companies which will segregate wood waste for us will also benefit," assures Jędrzej Kasprzak.

Poland already has several wood recycling lines, but the one being built in Żary is based on state-of-the-art solutions developed in recent years in Europe. It has been designed especially for SWISS KRONO. Its capacity is as much as 30 tonnes of raw material per hour.

- The installation will be completely clean, enclosed and emission-free, and therefore its operation will not affect local residents in any way, adds Jędrzej Kasprzak. - Chipped

post-consumed wood will be stored in an enclosed silo on the premises of the plant.

Milestone investment

The investment in the recycling line is ahead of the trend for recovering post-consumed wood. This has not yet reached Poland. Although at PSZOK points Poles can return bulk waste, i.e. furniture or woodwork, free of charge; however, this is still a small-scale activity.

- By building our line we are giving a clear signal to the recycling industry in Poland that we will soon be ready to accept large amounts of post-consumed wood that is currently lying on heaps," says Jędrzej Kasprzak. - They can increase selective collection of this type of waste from households and prepare it for recycling because we will accept it and make new boards from it. Unfortunately, at present such recycled raw material, after obtaining special permits, has to be imported because there is not enough of it in Poland. We hope that this will change.

Recycled woodchip to replace wood from the forest

The logistics processes involved in supplying recycled raw material to the SWISS KRONO plant will not generate much transport traffic. This will remain at a similar level as before, as post-consumed wood will be partially replaced by raw material from the forest - up to 100,000 m3 of roundwood per year.

- Recovery and reuse of used wood are necessary if we want to protect our forests and limit overexploitation of our natural resources - argues Tomasz Rola, Management Board Representative for Environmental Management System and Occupational Health and Safety at Swiss Krono. - By processing used wood, we eliminate many problems: we reduce the amount of stored waste and the costs incurred for its disposal. We also will secure an additional source of raw material, the shortage of which is becoming more and more evident – and not only in the panel industry.

Closed circuit

Recycling wood is a rational measure to support a circular economy, but it can also be profitable for producers. The supply of wood from forests is disproportionate to the needs of the market and its prices are constantly increasing. The availability of sawmill by-products, which are used to make panels, is also limited. The industry has to compete for sawdust and edgings with the energy sector, which buys huge quantities of them to generate energy from biomass subsidised as RES. Wood recovery and reprocessing is therefore not only justified from an ecological point of view, but is also necessary from an economic point of view.